SimsaInfra Project Pvt.Ltd has been consistently developing quality solutions that have played an integral part in growing India’s infrastructure. Simsa Infra has set a benchmark in the Metal roofing industries by establishing it as one of the topmost solution provider in Metal Building Systems extending the best service in the Pre-Engineered Buildings (PEB). Pre-engineered steel buildings are the building which is fabricated in the factory after designing, detailing, shipped to site; and all components are assembled and erected at site with nut-bolts & it helps to reduce the time of completion. The pre-engineered building system is the one of the fastest growing building systems in the world. Simsa Infra give an end to end solutions right from Design, Supply of Material and in-house trained technical team. We give a complete solution to our customers by fulfilling all the requirements of our customer in a specified time.

Our Various systems of PEB – Pre-Engineered Buildings :

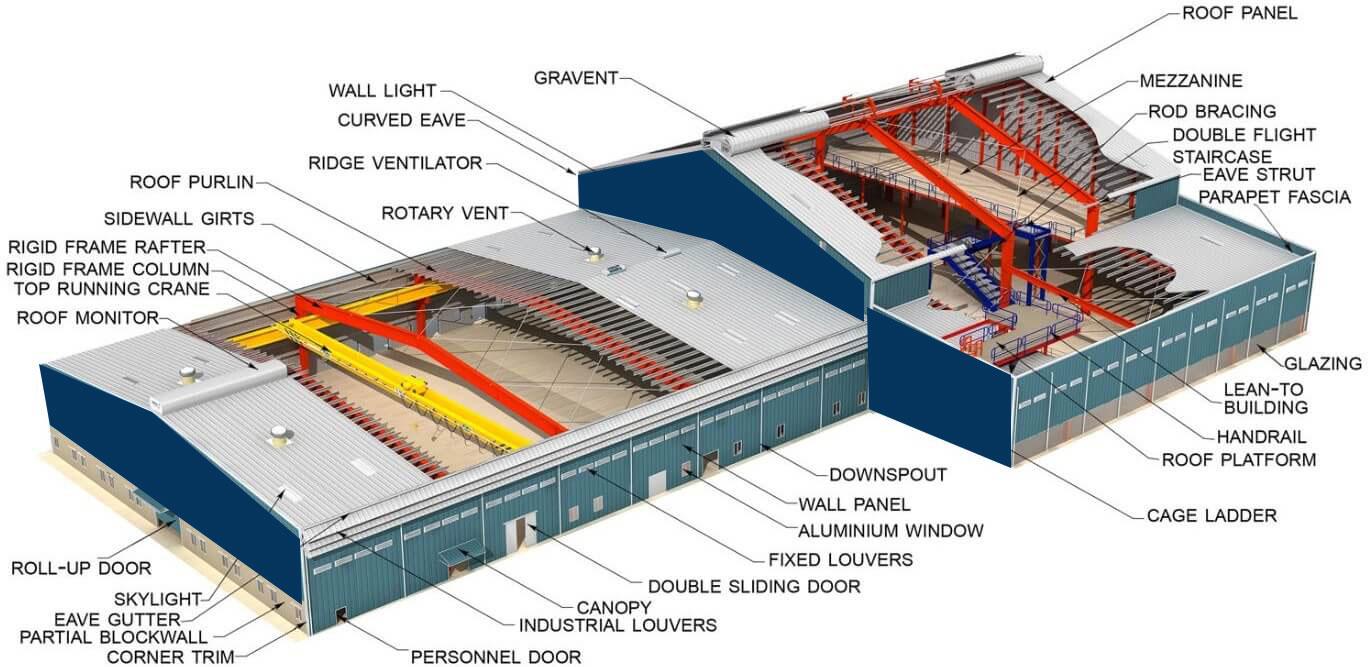

The PEB Structure of a building comprises of I-Beams (H- Beams), endwall wind columns, other forms of primary framing can include as trusses, mill sections rather than three-plate welded, castellated beams, etc. Secondary structural members (roof purlins & wall girts), wind bracing components and the structural framing of optional subsystems such as roof monitors, mezzanines (inclusive of mezzanine deck and desk fasteners), roof extensions, canopies, gantry cranes, fascias, parapets, interior partitions, roof & wall framed openings, anchor bolts, connection bolts and sag rods.

Various systems of PEB – Pre-Engineered Buildings:

Primary system:

This system involves tapered or parallel columns or tapered beams which are called rafters. Base of column is either fixed or pinned based on the load requirements.

Secondary system:

It consists of purlins, grits which are the side claddings and eave struts stiffened by sag rods. This system also includes the flange stiffeners which joins the untied flanges of the PEB primary system to the secondary system.

- Z and C purlins

-

Wind bracing system:

Rod bracing and the portal system are the two types of wind bracing systems. Each one is chosen accordingly depending on design and functional requirement.

-

Accessories:

This part includes the Turbo ventilator, ridge vents, Flashings, gutters, down pipes, ladders etc.

Advantages of PEB:

- Construction time: PEB reduces the total construction cost by the least 40% which leads to faster occupancy and early revenue.

- Lower cost: Saving is accomplished in design, manufacturing and erection cost.

- Large clear span: In PEB the buildings can be given up to 90m clear spans which is the important advantage of PEB with column free space.

- Flexibility of expansion: PEB can be easily expanded in length by adding additional bays.

- Quality control: PEB’s are manufactured under controlled conditions depending on the site and hence the quality is assured.

- Low maintenance: PEB’s have high quality paint systems for cladding which gives long durability and low maintenance costs

Application of PEB:

| Institutional |

|---|

| 1. Schools |

| 2. Exhibition Halls |

| 3. Hospitals |

| 4. Theaters |

| 5. Auditoriums |

| 6. Sports Halls |

| Heavy Industrial |

|---|

| 1. Cement Plants |

| 2. Steel rolling Mills |

| 3. Sugar Mills |

| 4. Recreational |

| 5. Gymnasiums |

| 6. Swimming Pool Enclosures |

| 7. Indoor Tennis Courts |

| Commercial |

|---|

| 1. Showrooms |

| 2. Distribution Centers |

| 3. Supermarkets |

| 4. Restaurants |

| 5. Offices |

| 6. Service Stations |

| 7. Shopping Centers |

| Aviation & Military |

|---|

| 1. Aircraft Hangers |

| 2. Administration Buildings |

| 3. Residential Barracks |

| 4. Support Facilities |

| Agricultural |

|---|

| 1. Poultry-Dairy Farms |

| 2. Greenhouses |

| 3. Grain Storage |

| 4. Animal Confinement |

|

5. Pump Stations |